Tube Laser Cutting Systems Menomonee Falls Wi

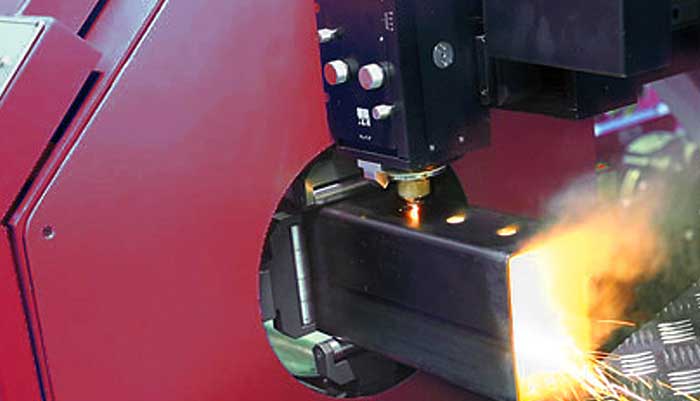

Fiber lasers are virtually maintenance-free, demonstrate superior wall plug efficiency when compared to traditional CO2 laser cutting machines, can cut reflective materials, and offer precise cutting. They also are faster than CO2 machines when cutting certain metal thicknesses. However, speed is relative when it comes to cutting tube. The real time savings comes from speeding up the processing time of the tube and producing finished parts.

North America's most important magazine for metal forming and fabricating, The FABRICATOR is the FABRICATOR. The magazine provides news, technical articles and case histories to help fabricators do their jobs better. Since 1970, the FABRICATOR has been serving the industry.